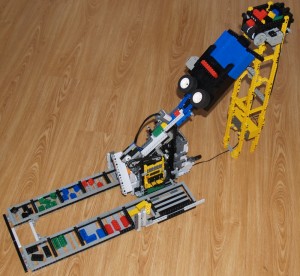

This is the fourth evolution of brick sorters! This time sorting 10 types of bricks: 5 colors and two sizes. You can simply throw a set of bricks into the sorter, and the machine will handle the rest. Compared to sorter #2, this one is more reliable and more functional too. This robot uses both the NXT and the RCX, with the NXT as master controller. The RCX is controlled by the NXT through a legacy controller provided by mindsensors.com. I’ll now discuss each of the components in the sorter in order, starting at the top, where a set of bricks is thrown into the machine.

Other brick sorters in this series:

Every time I created a new brick sorter, I tried to tackle a new design challenge. This improvement would make the robot more functional, more reliable, or both. Follow the links below, and read the pages in order to learn about my findings in the design process.

- Brick sorter #1: July 2006 (original design; 3 colors, 1 size)

- Brick sorter #2: December 2006 (3 colors, 2 sizes)

- Brick sorter 8527 (#3): March 2007 (NXT 1.0 only, 3 colors, 1 size)

- Brick sorter #4: July 2007 (5 colors, 2 size)

- Brick sorter #5: May 2008 (Custom color sensor, 6 colors, 1 size)

- Hybrid Brick Sorter (#6): June 2009 (NXT 2.0 Only, up to 6 colors, 1 size)

Exploring the sorting machine

Colored bricks of two sizes are put onto a conveyor belt, which repeatedly moves forwards and a little bit backwards, making one or two bricks fall into the temporary brick storage at the time. This mechanism is improved over the previous sorters, but it is still not perfect. Sometimes a brick gets stuck in the brick storage, making it impossible for the process to continue successfully. Once dropped off the conveyor belt, the bricks slide into the chute, through two turning wheels in the brick storage. If the light sensor in the chute detects any bricks, the conveyor belt at the top stops moving.

In the chute, the bricks are all nicely aligned. This makes it possible to push the first brick in the queue to the side, enabling it to slide down to the color sensor.

The sensor compartment consists of three modules. The brick lock, is used to keep a brick in the scanning compartment during the scan and to release the brick when done scanning. Depending on the size of the brick, the light sensor will see a drop in a light sensor value. A small LEGO light bulb, along with a phototransistor are used to read the color of the brick. This gave better results than using the regular LEGO light sensor, which is unable to distinguish yellow from red, for example.

Once the brick sorter knows the size of the brick, it will turn the brick slide, allowing a brick to go in either the left or right bins. Next, once the machine knows the color of the brick to be sorted, it moves the platform with bins in a way that if a brick is released, it falls in the correct brick collector bin.

Wow, that is cool!

that is so cool I wish there was instructions to it.