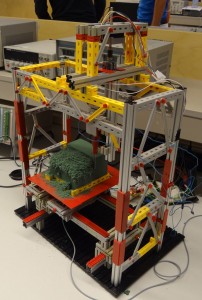

This machine was developed for Mechatronics class – second year bachelor Mechanical Engineering at TU Delft. It’s made from FischerTechnik because these were the tools available in class. Note that some LEGO parts (the linear actuator) made it in here. In fact, the idea was inspired by the LEGO Milling Machine by Arthur Sacek.

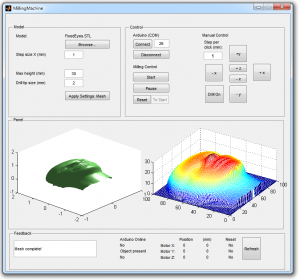

The system was made with a team of four students, so we split the tasks of building and programming. I focused mostly on the software hardware interface between Matlab and the Arduino. The Arduino runs 3 stepper motors and a DC motor, and takes input from four sensors. Most of the control program runs on Matlab, through a self made interface as shown below.

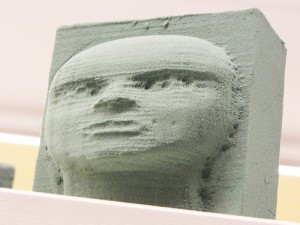

A 3D model can be made with most 3D software packages such as SolidWorks. The Matlab program converts the STL-file into a matrix of height levels. In turn, it tells the Arduino to move the motors to follow these landscape coordinates. The printed result is shown below. This was our first complete test we did with the deadline approaching. Luckily, it turned out well – but we had to take the thing apart after that.

Hello, please tell me – what a track is playing in your video? Thank you.

It’s called ‘Rocket’ by Kevin MacLeod from Incompetech.

hey there,

is it possible to get your matlab code?

i want to build a Lego cnc mill myself similar to Arthur Sacek’s but i have no idea how to convert an STL file..

regards Lukas

very nice efforts, great work….

Mit freundlichen Grüßen,

Syed Yasir Shah

Director

Industrial Automation

Can you give us your Matlab code and Arduino?

thank you!Dan